Extrusion of foods

Practical Action

Type of pasta

Description

Bucatini

Hollow spaghetti

Casarecce

Short curled up pasta

Chitarre

Square spaghetti

Fettuccine

Long flat pasta

Fusilli

Short twists

Lasagne

Sheet pasta

Linguine

Long thin oval pasta

Macaroni

Short hollow smooth pasta

Pappardelle

Long wide flat pasta

Penne rigati

Short hollow ridged pasta, angled cut

Reginette

Long flat wavy edged pasta

Rigatoni

Short hollow ridged pasta, straight cut

Rotelle

Wagon wheel shape pasta, with ridged rings and spokes

Spaghetti

Long round

Tagliolini

Long thin flat pasta

Table 1. Types of pasta (Product information from Fresh Pasta Machines at

www.freshpastamachines.co.uk/pasta_machines.html)

Different sizes of equipment are available, from small manual machines that are used in micro-scale

production and food service outlets, to larger electric machines. The equipment has a mixing

chamber, extruder barrel and a die for the desired pasta shape. There is debate over the best

material for dies, with some equipment manufacturers using stainless steel or plastic, and others

preferring bronze dies, which they claim imparts a rough surface to the pasta that holds sauce better

than pasta made by other methods. Shapes are cut to the appropriate length as they emerge from the

die, except rigatoni, which is extruded in long lengths and then cut to the correct size (straight for

rigatoni or angled for penne rigati). Pasta is cooked immediately in food service outlets, or dried by

processors for retail sale. It can also be frozen for up to six months.

Hot extrusion

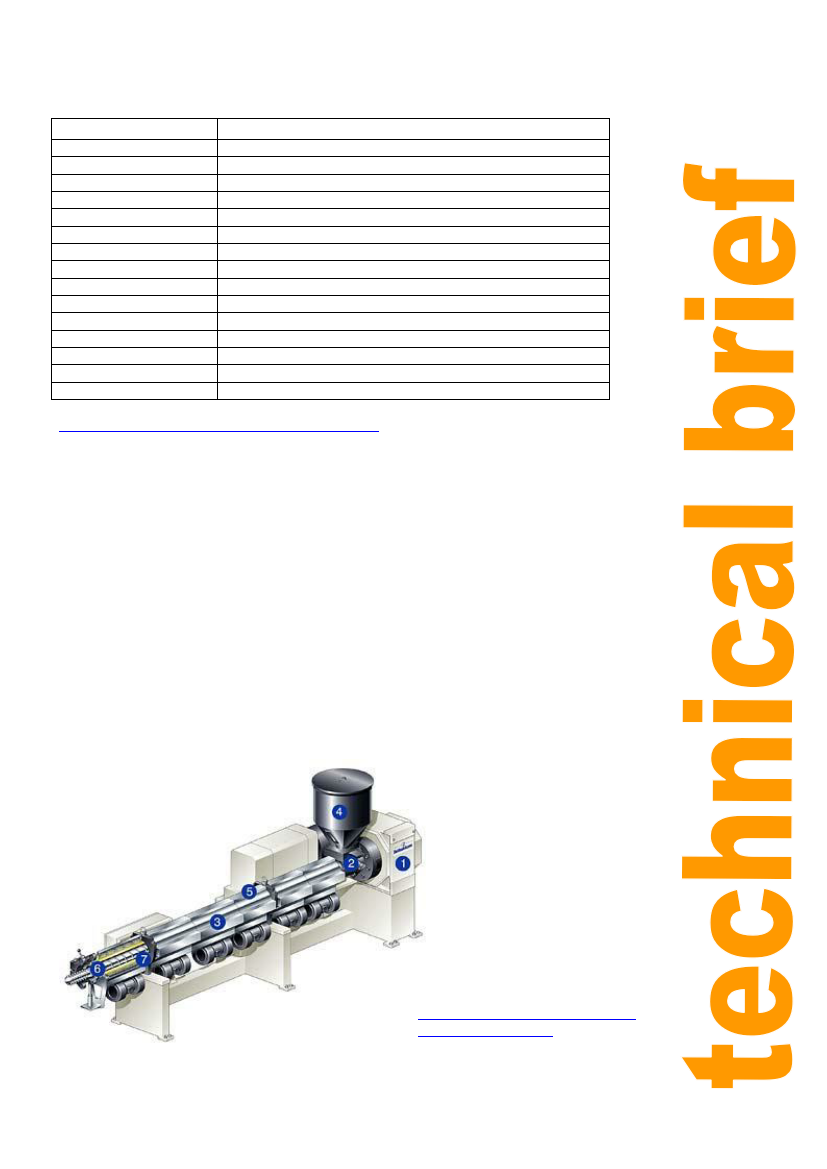

Extruder-cookers may be single- or twin-screw machines. Twin-screw machines have approximately

twice the capital and maintenance costs of single screw machines and are unlikely to be affordable

by most small-scale processors. Single-screw extruders (Figure 2) are therefore described in this

section. Processors, who wish to make extruded products such as or chocolate-filled snackfoods,

gums and jellies, marshmallows, cornflakes, or instant rice or noodles, should discuss their

requirements with manufacturers of twin-screw extruder-cookers.

Figure 2: Single-screw extruder

(Reifenhäuser Group at

www.reifenhauser.com/en/extruder/p

0056_ein_module.asp)

1 Drive unit, 2 Barrel inlet, 3

Temperature control, 4 Feed hopper

and dosing unit, 5 Vacuum venting,

6 Barrel, 7 Screw.

2